Embossing and debossing are the processes or creating either a raised or recessed image or design into paper, card, or other materials. Embossed patterns are raised up against the surface, whilst debossed patterns are sunken into it. Debossed designs can also then be filled with ink to accentuate the effect. These raised or recessed effects are able to provide an additional sensory experience, making the end product appealing both to the eyes, and to the hands.

Embossing and debossing are particularly becoming more popular in modern, minimalist designs, as the simple yet effective style of highlighting key information gives a fresher and more contemporary look. These designs can also be combined with other effects such as foiling or using different coatings to create a more luxurious final design or can be left as-is in a process called blind embossing.

This effect creates a three-dimensional effect that draws the eyes and the fingertips to the key information or elements. Most companies will choose to emboss their company logo or name in order to make their brand stand out as much as possible. Whilst embossing most commonly use paper or card stock, it can also be done on a wide range of materials, including metal, acrylic, cloth, and leather. This can make embossing the perfect finishing touch to notepads, diaries, or for corporate gifts. Our embossed leather notebooks go particularly well with our newest range of engraved pens or as part of our luxurious pen sets.

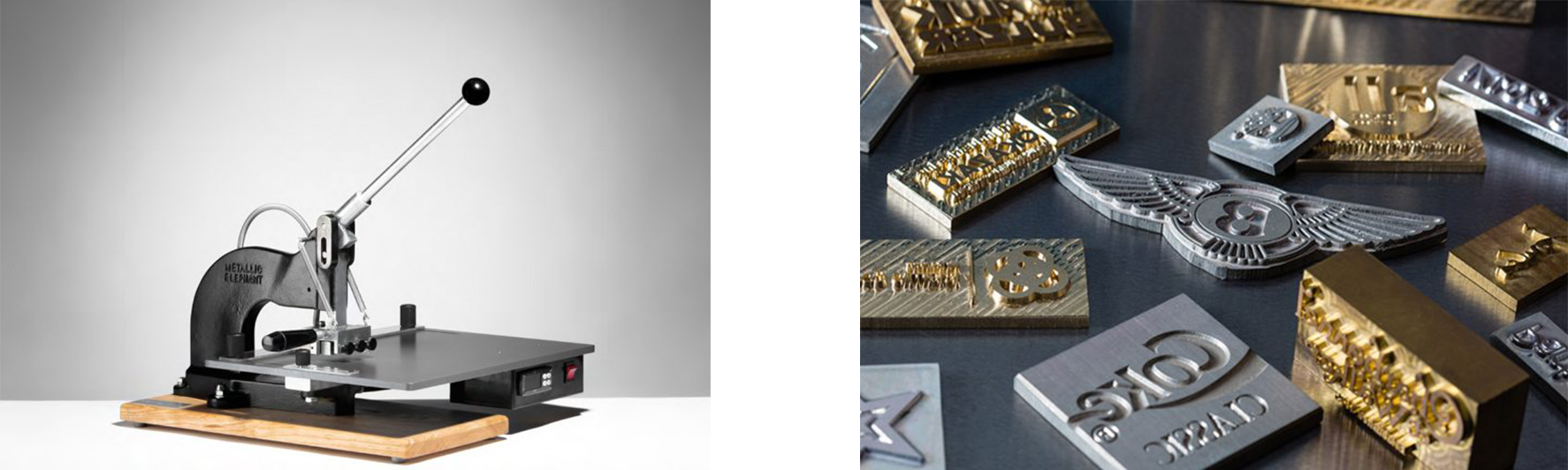

Embossing requires two key elements, the stock (paper), and the die. The die refers to a metal plate that has been specially cut into the required design or image that is to be embossed. The die will then be pressed into the stock (in a similar method to stamping) in order to raise the image slightly from the paper to create a more 3-dimensional effect. These raised images can be based on a single-level depth, or multi-level for a more complex design using variations of height and depth. The process of embossing is also most popularly used for braille translations and on credit and debit cards, as well as on more luxurious items such as stationery and leather goods.

What is Debossing?

As the opposite of embossing, debossing is the process of imprinting a design into the printing to create a recessed effect. Similar to embossing, this can then be filled with either ink or foil for a coloured effect, or can be left as it is for a sleeker style. An advantage to debossing instead of embossing is that it doesn’t affect the appearance of the back side of the printing surface, leaving both sides fully useable without having to make any concessions.

How is it done?

The process of embossing begins with the die, which is made up of two metal plates on the front and back (sometimes known as a counterdie). The paper or other printing surface is then sandwiched between the two. The die can be made either by hand-tooling, routering, or photo etching the logo or image onto the plates. The plates are then positioned with the printing surface between them, the female die on top, and the male on the bottom. This is reversed for debossing, with the female acting as the couterdie to the male on top. The plates are then pressed into the printing surface using both heat and pressure to create a relief of the logo or image.

The Key Benefits of Embossing and Debossing

Draws Attention - The tactile experience and the visual effect helps to focus the reader or viewers’ attention to the most vital information, whether that is a company name, logo, or initials on a personalised notebook.

Adds Texture – The effect of touch on marketing materials and luxury items can prove to be incredibly captivating to anyone handling them, and is guaranteed to make a company stand out amongst competitors.

Increases Perceived Value – Not only are embossed or debossed products more visually and physically interesting, but they also convey a much higher perceived value due to the quality of finish that it provides.

The Considerations of Embossing and Debossing

Use Vectored Artwork – Because vectored files are made up of mathematical rules and measurements, they can be easily resized without compromising on quality. The use of vectored artwork is therefore key to providing the smoothest finish on an embossed or debossed product.

Be Selective – The key aspect to embossing or debossing is to draw attention to the key element or elements of the printed surface, therefore it is better off being used as an accent for specific pieces of information. This being said, there are no hand-and-fast rules to follow.

Keep It Simple – Because of the plates and use of dimensionality with embossing and debossing, it is best to use simpler artwork and imagery. Shading and colouring can unfortunately be left distorted following the embossing and debossing process.

Heavier Works Better – Heavier card stocks tend to create the most effective pieces of embossing or debossing. This is especially the case for more detailed die patterns as heavier stocks and thicker materials tend to highlight the pattern better.

Consider the Back – This is more so the case for embossed items as embossed patterns will effect the design on the back of the printing surface. This doesn’t always have to be a limitation and could provide the opportunity for more creative visuals to encompass both sides.